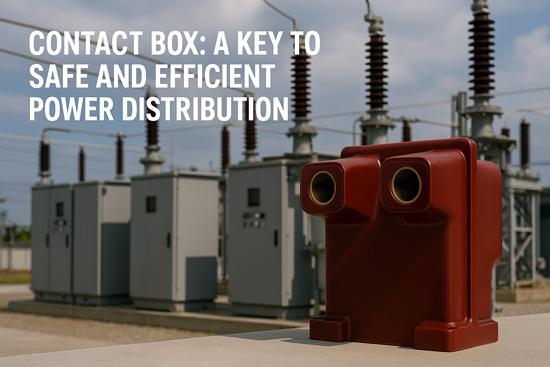

In medium-voltage switchgear systems, the Contact box plays a pivotal role in ensuring electrical safety, insulation reliability, and long-term operational efficiency. As electrical networks become more compact and demand more precise performance, the quality and design of contact boxes have drawn increasing attention from system engineers and procurement specialists alike.

A high-performance contact box is not just a housing component—it is a critical safety and performance element in vacuum circuit breakers and ring main units (RMUs). It facilitates the safe separation and insulation of conductive parts, helping to prevent arc flash incidents and improve system reliability.

Here are several key aspects that make contact boxes essential:

High Insulation Strength

Made from epoxy resin or other composite insulation materials, contact boxes offer excellent dielectric properties, even under high-voltage stress and environmental fluctuations.

Dimensional Precision and Compatibility

Accurate molding ensures seamless alignment with copper conductors, vacuum interrupters, and bushings. This reduces contact resistance, improves heat dissipation, and extends the life of the switchgear.

Thermal and Mechanical Stability

Contact boxes are subjected to intense thermal cycling and mechanical vibration. Quality materials and precise manufacturing minimize the risk of cracking, deformation, or insulation breakdown over time.

Customizability for Multiple Applications

Modern contact boxes are available in various sizes and configurations to meet the needs of 12kV, 24kV, and 36kV systems, enabling quick integration with various switchgear models.

Applications Across the Power Grid

Vacuum Circuit Breakers (VCBs)

Ensuring arc-free operation and improved contact separation.

Ring Main Units (RMUs)

Providing compact, reliable insulation in confined spaces.

Compact Substations and Switch Cabinets

Supporting modular, maintenance-friendly power equipment solutions.