In medium- and high-voltage systems, instrument transformers—commonly known as CTs (current transformers) and VTs (voltage transformers)—play a vital role in accurate measurement, safe operation, and reliable protection. Choosing the right type of instrument transformer is no longer a matter of specification alone—it’s a key step in ensuring system performance and cost-efficiency.

Common instrument transformers are responsible for scaling down high voltages and currents to measurable levels for relays, meters, and monitoring systems. But not all instrument transformers are created equal—differences in insulation type, accuracy class, and installation environment can significantly affect long-term reliability.

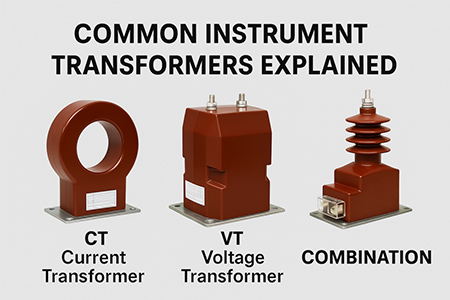

1. Current Transformers (CTs)

Used for measuring current and protecting equipment. Common designs include:

- Window-type CTs: Simple, compact, ideal for indoor switchgear

- Bar-type CTs: Used where the primary conductor is integral to the CT

- Wound-type CTs: Offer higher accuracy for metering

2. Voltage Transformers (VTs or PTs)

Provide scaled-down voltage for metering and relays. Variants include:

- Inductive VTs: Durable, cost-effective for general use

- Capacitive VTs (CVTs): Suitable for high-voltage outdoor systems, often with built-in communication capabilities

3. Combined CT/VT Units

Compact designs integrating both measurement functions, often used in ring main units (RMUs) and space-constrained substations.

1、What accuracy class should I select?

Depends on whether the device is for protection (5P, 10P) or metering (0.2, 0.5 class).

2、Indoor vs. outdoor application?

Epoxy-resin encapsulated for indoor use; oil-paper or gas-insulated for outdoor systems.

3、Primary current range and burden?

Always ensure the selected CT matches the expected operational load and connected device impedance.

Procurement managers and electrical engineers know: improper instrument transformer selection leads to inaccurate readings, nuisance tripping, or equipment failure. Choosing a reliable, tested, and appropriately rated CT or VT minimizes these risks from the start.

Epoxy Resin:Provides durable insulation and mechanical strength

Indoor Installation:Designed specifically for indoor use

Standard Frequency:Supports 50Hz or 60Hz operation

Load Power Factor:cosΦ=0.8 (lagging) for efficient energy use

Standards Compliant:Meets IEC 60044-2 & IEC 61869-1/3 for quality and safety

Reliable Operation:Stable power supply performance in medium voltage systems