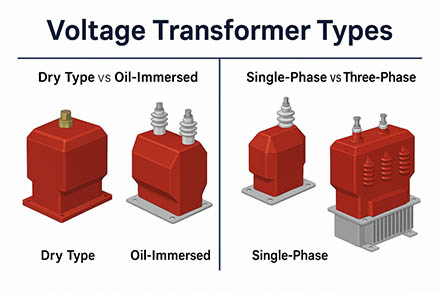

Voltage transformers (VTs) are essential components in medium and high voltage systems, enabling accurate voltage measurement and protection. As the demand for grid modernization grows, understanding the major types of VT structures—particularly the differences between single-phase and three-phase, and dry-type and oil-immersed VTs—becomes a priority for engineers, EPCs, and procurement professionals.

Single-phase VTs are widely used in systems where monitoring or protection of a single phase is required. These are compact, cost-effective, and suitable for applications such as metering transformers or in substations with limited space.

Three-phase VTs, on the other hand, provide an integrated solution for full three-phase voltage measurement. They are often used in industrial or utility-scale environments where consistent phase relationship and simplified installation are crucial.

Dry-type VTs are built with cast resin insulation and do not require liquid for cooling. Their maintenance-free design and enhanced safety make them ideal for indoor installations, particularly in urban substations, underground facilities, and compact switchgear systems.

Oil-immersed VTs are traditionally used in outdoor or high-load environments. The oil provides both insulation and cooling, extending lifespan and thermal endurance. They are highly reliable and still preferred in some utility-grade networks, especially in high-voltage outdoor applications.

The selection of VT type depends on several factors:

☆Installation environment (indoor vs outdoor)

☆Voltage level and load requirements

☆Maintenance constraints

☆Size and cost considerations

Both dry-type and oil-immersed VTs—whether single-phase or three-phase—play important roles in achieving accurate voltage monitoring, stable operation, and long-term reliability.