Indoor termination loads are essential components in medium-voltage cable systems, serving as the secure, insulated interface between power cables and indoor equipment such as switchgear, transformers, and control panels. With diverse operating environments and technical demands, buyers increasingly ask: Which type of indoor termination load fits my application best?

A well-matched termination ensures safe current transfer, prevents insulation failure, and reduces downtime due to partial discharges or overheating. Improper selection may lead to arc flash hazards, poor sealing, or thermal aging—especially in enclosed indoor environments.

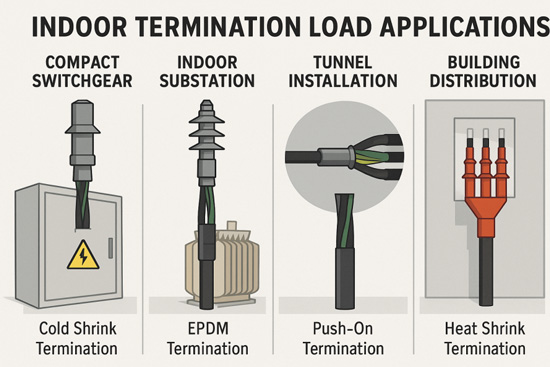

Key Use Scenarios & What to Choose

1. For Compact Switchgear Cabinets

In dense switchgear rooms, space is limited. Choose cold shrink terminations for their ease of installation without heat tools. Their elastic silicone bodies adapt well to tight spaces.

2. In High-Humidity Indoor Substations

In underground or coastal substations, where humidity is a challenge, EPDM-based indoor terminations with double-sealing structures are preferred. Moisture ingress is a leading cause of failure.

3. For Tunnels, Metro & Rail Systems

Environments with strong vibration or narrow tunnels benefit from push-on or pre-molded terminations that offer vibration resistance and quick reworkability.

4. For Building Distribution Panels

Where systems require minimal thermal expansion or easy retrofitting, heat shrink terminations provide a cost-effective and compact solution with strong adhesive bonding.

Voltage rating: 6–35kV (commonly used for XLPE cables)

Cable compatibility: Core size, insulation diameter, number of cores

Standards compliance: IEC 60502-4, IEEE Std 48, or local grid standards

Stress control design: Integral stress cone or mastic-based grading

Insulation materials: Silicone rubber, EPDM, heat-shrinkable polyolefin

·Can this termination handle surge conditions indoors?

Yes—look for terminations with capacitive grading or built-in surge resistance.

·Does it require special tools or heat sources?

Cold shrink kits eliminate heating tools, while heat shrink types require only a torch.

·Is there a universal kit for all cable sizes?

Most kits are size-specific. Using the correct model ensures optimal sealing and stress control.