Power transformer bushings are critical components for safely transmitting electrical energy between the internal windings of a transformer and external systems. Their quality and compatibility directly influence transformer reliability, dielectric performance, and maintenance cycles.

As grid systems become more complex, selecting the right type of bushing for your specific voltage and operational environment has become a top concern for engineers, utilities, and OEM buyers.

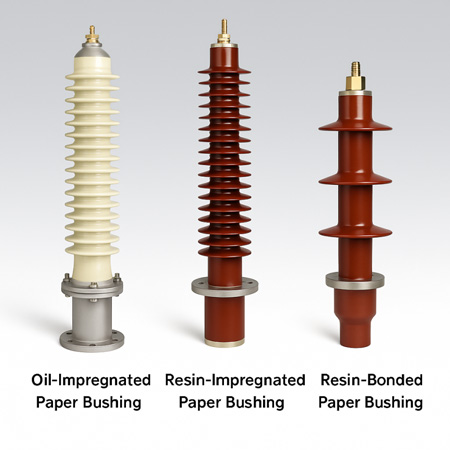

Today’s power transformer bushing products are available in several technologies and voltage classes. Understanding the key options can help buyers make more informed decisions.

1. Oil-Impregnated Paper (OIP) Bushings

Widely used in high-voltage transformers (≥72.5kV), OIP bushings offer excellent dielectric strength and long service life. They require regular monitoring and are sensitive to moisture.

2. Resin-Impregnated Paper (RIP) Bushings

With superior moisture resistance and a dry insulation system, RIP bushings are gaining popularity in harsh or humid environments. They reduce the risk of oil leakage and are maintenance-friendly.

3. Resin-Bonded Paper (RBP) Bushings

Typically used in medium-voltage applications (≤36kV), RBP bushings provide a cost-effective and compact solution for standard-duty installations.

4. Capacitive-Graded vs. Non-Capacitive

Capacitive-graded bushings are designed for higher voltages, ensuring even voltage distribution along the insulation path. For lower voltages or simple applications, non-capacitive bushings may suffice.

|

Voltage Class |

Recommended Bushing Type |

Typical Use Cases |

|

≤36kV |

RBP / Low-voltage RIP |

Distribution transformers, pole-mounted units |

|

40–72.5kV |

RIP / Small OIP |

Industrial and urban grid systems |

|

≥110kV |

OIP / High-grade RIP |

HV substations, transmission transformers |

|

≥220kV & special duty |

Custom OIP with tap connections or RIP bushings |

UHV systems, intertie transformers |

When selecting bushings, ensure compatibility with system insulation coordination, transformer geometry, and operating temperatures. Factory testing per IEC 60137 or ANSI/IEEE C57.19 standards is also essential.

Using the right bushing type not only ensures electrical safety but also reduces the total cost of ownership. Modern bushings with integrated monitoring (such as tan delta sensors or thermal detectors) support condition-based maintenance strategies, improving grid resilience and uptime.