Voltage transformers (VTs), also known as potential transformers (PTs), are essential components in medium- and high-voltage systems. Their main role—accurately stepping down voltage for measurement, protection, and control—makes them vital across various applications. As power grids grow more intelligent and safety standards more rigorous, understanding where and how voltage transformers are used is more important than ever.

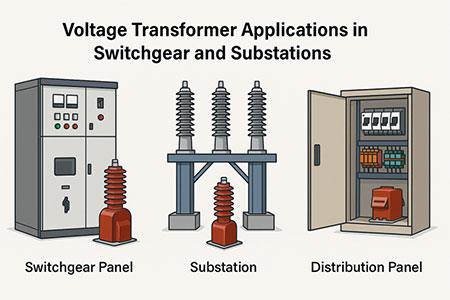

1. Switchgear Panels (MV and HV)

VTs are embedded within metal-enclosed or gas-insulated switchgear (GIS/AIS) to provide precise voltage signals to protection relays, meters, and SCADA systems. Their compact size and integration with isolators and circuit breakers make them ideal for safe and efficient grid operation.

2. Substations

In primary and secondary substations, VTs help monitor grid health and provide feedback for automatic load management. Their insulation class, mounting design (pole, wall, or busbar), and compliance with IEC/IEEE standards are key selection factors.

3. Distribution Panels

In low-to-medium voltage distribution panels, indoor resin-cast or epoxy-insulated VTs are used to support commercial energy metering, feeder protection, and network diagnostics. Their role is especially critical in commercial buildings, industrial complexes, and critical infrastructure.

4. Renewable Energy Systems

VTs are used in solar and wind collector stations to ensure inverter synchronization, detect over/under voltage events, and contribute to grid compliance in variable generation conditions.

Voltage Accuracy Class: Choose according to measurement or protection needs (e.g., 0.2 for metering, 3P for protection).

Insulation Type: Epoxy, resin, or oil-paper, depending on indoor/outdoor use and pollution level.

Mounting Compatibility: Ensure mechanical fit with existing panel or pole configurations.

Standards Compliance: IEC 61869, IEEE C57, and local utility specifications must be met.

Thermal Performance: Especially important for compact switchgear environments.

For modern indoor applications, epoxy-encapsulated voltage transformers offer clear advantages:

☆Smaller footprint

☆No oil leakage risks

☆High partial discharge resistance

☆Simplified maintenance

These features align with the needs of smart switchgear and space-constrained substations.

Epoxy Resin:Provides durable insulation and mechanical strength

Indoor Installation:Designed specifically for indoor use

Standard Frequency:Supports 50Hz or 60Hz operation

Load Power Factor:cosΦ=0.8 (lagging) for efficient energy use

Standards Compliant:Meets IEC 60044-2 & IEC 61869-1/3 for quality and safety

Reliable Operation:Stable power supply performance in medium voltage systems