ZW32-12kV outdoor pole-mounted vacuum circuit breaker is a three-phase AC 50Hz/60Hz primary switching device rated for 12kV. It is designed to break and close load, overload, and short-circuit currents, mainly used in power distribution networks of substations, industrial and mining enterprises, and rural grids with frequent operations.

Equipped with advanced vacuum interrupters and integrated isolation switch, it offers reliable fault isolation and protection. The product can be paired with controllers to support distribution automation and traditional recloser functions.

| No. | Items | Unit | Value |

| 1 | Rated voltage | kV | 12 |

| 2 | Rated current | A | 630, 1250 |

| 3 | Rated frequency | Hz | 50/60 |

| 4 | Rated short-circuit breaking current | kA | 20, 25 |

| 5 | Rated peak withstand current | 50, 63 | |

| 6 | Rated short-time withstand current (4s) | 20, 25 | |

| 7 | Rated short-circuit making current (Peak) | 50, 63 | |

| 8 | Number of Mechanical Operations | Time | 10000 |

| 9 | Rated operating sequence | O-0.3s-CO-180s-CO | |

| 10 | Rated power-frequency withstand voltage (1min): Between phases and Phase to earth |

kV | 42 |

| 10 | Rated power-frequency withstand voltage (1min): Across the isolating distance. |

48 | |

| 11 | Rated lightning impulse withstand voltage (Peak): Between phases and Phase to earth |

kV | 75 |

| 11 | Rated lightning impulse withstand voltage (Peak): Across the isolating distance. |

85 | |

| 12 | 1 min power frequency withstand voltage of secondary circuit | kV | 2 |

| 13 | Net Weight | kg | 85 |

| No. | Items | Unit | Value |

| 1 | Contact spacing | mm | 8~10 |

| 2 | Contact overtravel | 2~3 | |

| 3 | Average closing speed | m/s | 0.75±0.2 |

| 4 | Average opening speed | 1.25±0.2 | |

| 5 | Contact closing bounce time | ms | ≤2 |

| 6 | Three-phase opening Simultaneous time difference | ≤2 | |

| 7 | Closing time | ≤60 | |

| 8 | Breaking time | 20~60 | |

| 9 | Each phase circuit resistance | μO | ≤80 |

| 10 | Conductive loop resistance per phase (With disconnecting switch) |

<200 | |

| 11 | Distance between phases outside the box | mm | 340±3 |

| 12 | Allowable cumulative wear thickness of dynamic and static contacts |

3 |

| Items | Rated operating voltage(V) | Rated power | Rated operating current (A) | Normal working range |

| Motor | -200 | 40 | 0.5 | 85%-110% rated operating voltage |

| -110 | ||||

| -48 | 1.8 | |||

| -24 | 4.6 | |||

| Opening and Closing Coil |

-220 | 372 | 1.69 | Opening: 65%-120% rated operating voltage, 30% rated Voltage should not trip. |

| -110 | 374 | 3.4 | ||

| -48 | 480 | 10 | ||

| -24 | 276 | 11.5 |

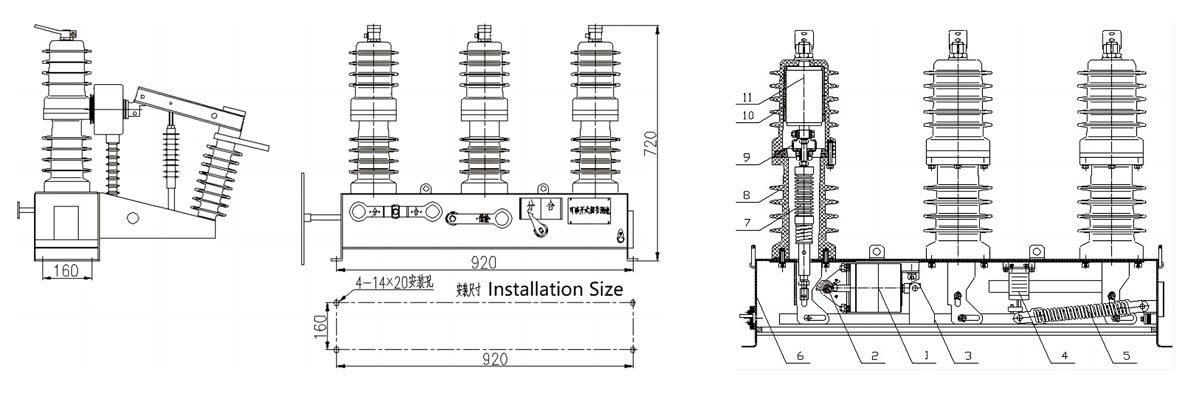

The breaker adopts a three-phase separated column design with each phase installed in its own insulating sleeve. The vacuum interrupter uses a ceramic shell and copper-chromium contacts with a longitudinal magnetic field arc extinguishing method for reliable breaking. The vacuum chamber is sealed in a silicone rubber sleeve, ensuring 20 years of maintenance-free operation. The insulating cylinders are made of outdoor epoxy or silicone rubber, offering strong hydrophobicity and pollution resistance. The operating mechanism can be permanent magnet or spring type, installed in a fully sealed box for moisture and rust protection. External current transformers and composite controllers with anti-inrush functions are installed on phases A and C. An isolation switch with mechanical interlock is included to prevent misoperation.

The circuit breaker operates reliably in ambient temperatures from -40°C to +40°C, at altitudes up to 2000 meters, and under wind pressures up to 700Pa. It withstands pollution level IV and earthquakes up to 8 degrees. Regular maintenance includes inspection every 5 years, cleaning insulating parts, greasing moving parts, checking fasteners, and performing electrical tests. The breaker should be cycled several times annually if rarely operated. Safety precautions must be observed during maintenance due to stored mechanical energy in the operating mechanism. Customization is available upon request.

The parameters listed above are standard references. If these styles do not fulfill your specific requirements, feel free to reach out to us for a bespoke design. With strong capabilities in personalized development and production, we offer tailored solutions to clients worldwide.