The GW4 disconnector is a widely recognized and field-proven type of high-voltage disconnect switch, known for its robust mechanical structure, reliable isolation capability, and excellent adaptability in outdoor substations. In systems where safety, maintainability, and long-term stability are essential, GW4 remains a top choice among engineers and utility operators.

As the energy sector pushes toward higher reliability and safety standards, the GW4 disconnector has gained attention for several practical advantages:

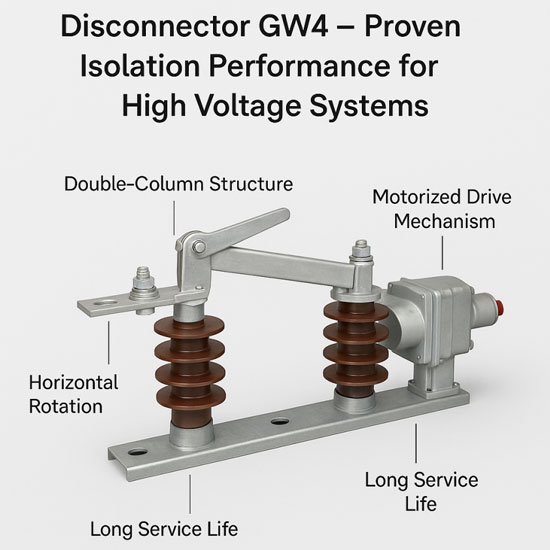

Double-Column Structure

The GW4 features a dual-insulator support design, providing strong mechanical stability, particularly in outdoor environments exposed to wind, snow, or pollution.

Horizontal Rotation & Visible Isolation

With its horizontal rotary blade mechanism, the GW4 ensures safe and clear disconnection that operators can visibly confirm, significantly enhancing field safety.

Strong Customization Compatibility

The GW4 can be configured with manual or motorized drive mechanisms, with optional earthing switches, making it adaptable to different voltage levels (typically 35kV to 252kV) and substation layouts.

Long Service Life

Built using corrosion-resistant materials such as hot-dip galvanized steel and UV-resistant composite insulators, GW4 disconnectors perform reliably even in demanding conditions.

Simple Maintenance

Designed for easy inspection and mechanical lubrication, the GW4 minimizes maintenance costs over time, which is vital for utilities looking to reduce long-term O&M expenses.

·Transmission and distribution substations (35–220kV)

·Power plants

·Industrial high-voltage equipment grids

·Renewable energy integration points

In all these applications, GW4 helps ensure safety during equipment maintenance and system upgrades by providing clear, reliable electrical isolation.