In medium and high voltage power systems, electrical insulation is not just a supporting component—it is a critical factor that directly impacts safety, reliability, and long-term operation. An effective and integrated electrical insulation solution must be built on material quality, structural design, and system compatibility to ensure performance across the entire equipment lifecycle.

Throughout daily operation, electrical equipment is exposed to voltage stress, thermal cycles, humidity, pollution, and mechanical vibrations. Therefore, a consistent and dependable insulation system must offer long-term resistance to electrical breakdown, aging, surface tracking, thermal shock, and environmental challenges.

When designing or selecting an insulation solution, several key factors must be considered:

1、Material Selection and Performance Criteria

Different applications require different insulation materials. For example, epoxy resin is widely used where both mechanical and electrical strength are essential, while silicone rubber performs well in outdoor or high-pollution environments. Key parameters include CTI, UV resistance, and thermal stability.

2、Creepage Distance and Structural Design

Proper creepage distance is crucial to avoid flashovers, especially in humid or dusty environments. The structure must also ensure effective heat dissipation, sealing, and contamination resistance.

3、System Integration and Modularity

With the trend toward modular switchgear, substations, and pole-mounted units, it’s important that insulation components are not only individually reliable but also system-compatible. A well-matched insulation system improves overall reliability and reduces maintenance risks.

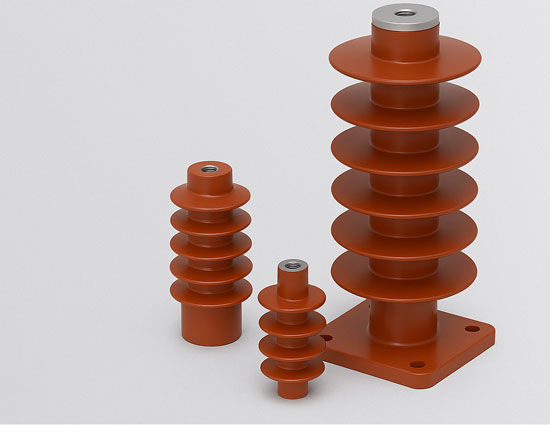

Within this framework, Putai’s epoxy resin insulators offer high dielectric strength and mechanical stability. These insulators are widely applied in 12kV to 40.5kV switchgear and ring main units, supporting OEMs in delivering robust and consistent insulation performance.