In transformer design and maintenance, bushing type selection plays a decisive role in long-term reliability, operational safety, and cost efficiency. Among the most commonly compared options are RIP bushings (Resin Impregnated Paper) and OIP bushings (Oil Impregnated Paper).

Understanding their differences is not just a technical preference—it can directly impact insulation life, failure risk, and total cost of ownership.

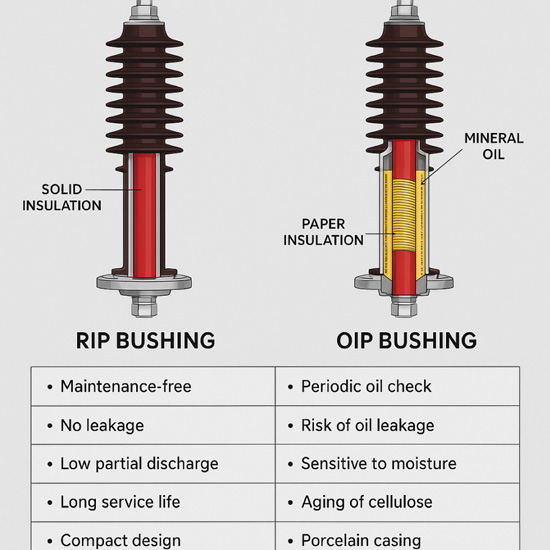

OIP Bushing: Consists of paper insulation soaked in transformer-grade mineral oil. The bushing is usually sealed with porcelain housing and connected directly to the transformer oil system.

RIP Bushing: Uses paper insulation impregnated with epoxy resin under vacuum, forming a solid dielectric without internal oil. The bushing is typically dry-type and fully encapsulated.

Hotspot Comparison – What Buyers Care Most About

|

Feature |

RIP Bushing |

OIP Bushing |

|

Maintenance |

Maintenance-free |

Requires periodic oil checks |

|

Leakage Risk |

No oil, no leakage |

Potential oil seepage over time |

|

Partial Discharge |

Lower risk due to solid insulation |

More sensitive to moisture ingress |

|

Service Life |

Up to 30 years with minimal aging |

Can degrade if oil quality declines |

|

Installation |

More compact, often lighter |

Heavier, porcelain casing required |

|

Cost |

Higher upfront cost |

Lower initial investment |

1、OIP bushings are still widely used in older transformer fleets, or where procurement budgets are limited.

2、RIP bushings are increasingly preferred for:

Compact substation designs

High-altitude or humid environments

Urban installations where oil leakage is a safety concern

GIS-connected transformers where partial discharge sensitivity is critical

In recent years, many transformer OEMs have begun offering RIP bushings as standard on their newer models due to their dry design, better environmental safety, and reduced routine maintenance requirements.

Several utilities are also retrofitting legacy OIP bushings with RIP versions during scheduled overhauls to improve equipment availability and reduce oil management effort.

When sourcing RIP or OIP bushings, it’s crucial to verify:

·Type test certifications (especially AC withstand, PD level, lightning impulse)

·Compatibility with your transformer oil system (for OIP)

·Interface standards (flange, conductor connection)

·Supplier delivery lead time and mold availability for custom ratings

Suppliers like PUTAI Electric offer custom-designed epoxy RIP wall bushings and support 24kV–35kV ranges commonly used in compact substations and distribution transformers, with low PD performance (≤5pC) and stable batch repeatability.