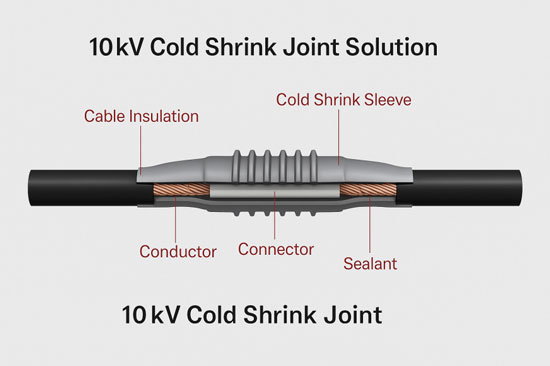

In medium-voltage power distribution systems, the reliability of cable connections is critical. The 10kV cold shrink intermediate joint solution has become a preferred choice for many installers and utility engineers thanks to its tool-free installation, excellent sealing performance, and long-term reliability in harsh environments.

1. Tool-Free, Quick Installation

Cold shrink joints are pre-expanded and held in place by a removable core. During installation, the core is pulled out, allowing the insulating sleeve to shrink and form a tight seal around the cable. This eliminates the need for heat guns or torches—making it ideal for confined spaces or flammable environments.

2. Excellent Sealing and Insulation

The silicone rubber used in cold shrink sleeves offers superior elasticity, UV resistance, and water tightness. This ensures excellent insulation even under frequent thermal cycling or high humidity conditions—critical for outdoor and underground installations.

3. Wide Cable Compatibility

These joints accommodate a variety of cable types including XLPE and EPR insulation, copper or aluminum conductors, and both single-core and multi-core configurations. A single kit often covers multiple cable sizes, reducing inventory costs.

4. Reliable Electrical Performance

Rated for 10kV systems, the joint ensures stable electrical insulation, low partial discharge, and arc resistance. It meets IEC and GB standards, offering peace of mind for long-term service.

5. Reduced Installation Risk

Compared with heat-shrink or resin-poured joints, cold shrink minimizes installation error. There is no need for curing time or heating, and the shrinkage is uniform and consistent every time.

10kV urban power grid cable networks

Medium-voltage branch box or feeder connections

Industrial facilities with high operational demands

Renewable energy installations (e.g., wind, solar farms)

Repair and retrofit of aged MV cables