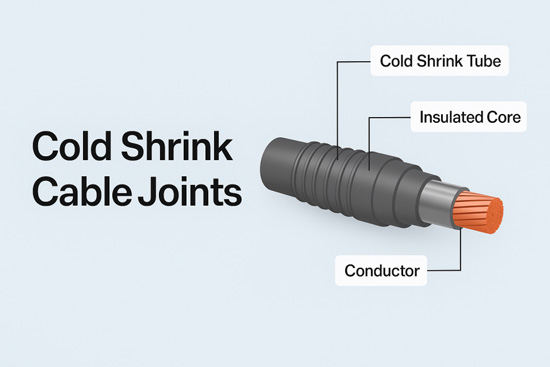

In today’s fast-paced electrical engineering projects, time, safety, and installation reliability are all critical. Cold shrink cable joints have emerged as a leading solution, especially in medium- and high-voltage applications, for their ease of use, consistent performance, and superior sealing capabilities.

Traditional heat-shrink joints require open flames or heating equipment, introducing safety risks and inconsistencies in field conditions. In contrast, cold shrink joints are factory-expanded and held in place by a removable core, allowing quick installation without tools or heat. This not only reduces installation time but also enhances sealing uniformity across projects.

✅ Tool-Free, Flame-Free Installation

Perfect for enclosed spaces, oil & gas environments, and utilities that prioritize fire safety.

✅ Consistent Sealing Pressure

The pre-stretched silicone or EPDM material contracts tightly around cables, maintaining a moisture- and dust-proof seal over time.

✅ High Voltage Performance

Cold shrink joints can be designed for 10kV, 15kV, 24kV, or 35kV systems, making them ideal for wide deployment across distribution grids.

✅ Simplified Inventory and Training

Fewer product variants and simplified installation steps make procurement and training more efficient.

✅ Long-Term Durability

UV-resistant, hydrophobic materials ensure long service life even in harsh outdoor or underground conditions.

·Underground medium-voltage cable connections

·Renewable energy installations (solar, wind farms)

·Urban substations and residential utility networks

·Industrial plants and chemical zones requiring flame-free environments

·Emergency cable restoration kits

Are the joints pre-tested to IEC standards?

What is the recovery range and diameter tolerance?

Is the product compliant with specific utility or regional standards?

Can it handle thermal cycling in outdoor applications?