In the evolving landscape of urban power grids and compact substation design, gas insulated substation bushings (GIS bushings) are becoming the preferred solution for engineers and procurement teams seeking space efficiency, operational safety, and long-term reliability.

These bushings are no longer just passive components—they are enablers of high-density substations and uninterrupted grid operation in metropolitan and mission-critical environments.

Urban substations demand components that do more in less space. GIS bushings meet this need with:

Minimal footprint, ideal for underground or enclosed installations

Sealed SF6 insulation, delivering high dielectric strength and arc resistance

No external contamination, reducing maintenance frequency

Integration-ready design, ensuring seamless connection with GIS compartments

For procurement managers comparing vendors, the following features are now standard evaluation metrics:

✅ High Voltage Endurance

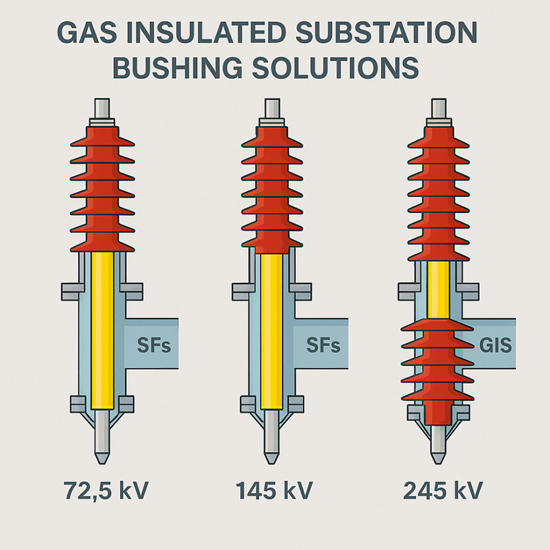

Withstand voltage levels up to 245kV or higher, suitable for primary distribution and transmission substations.

✅ Tested Gas Integrity

Each bushing undergoes SF6 leakage detection, pressure endurance, and temperature cycling tests before delivery.

✅ Custom Flange Interfaces

Bushings designed with customized mounting flanges fit both standard and retrofitted substation walls.

✅ Low Partial Discharge Performance

Precision molding and shielded paths ensure PD < 5pC, even under high humidity or thermal stress.

Urban GIS substations beneath commercial buildings or roadways

Coastal and chemical zone substations requiring enclosed insulation

Renewable energy hubs with limited footprint

Data center or hospital backup substations needing low-maintenance insulation

GIS bushings reduce risks associated with contamination, corrosion, and aging. Their sealed nature ensures fewer failure points, while pre-tested delivery minimizes onsite integration risk—both of which are key metrics in EPC performance contracts.