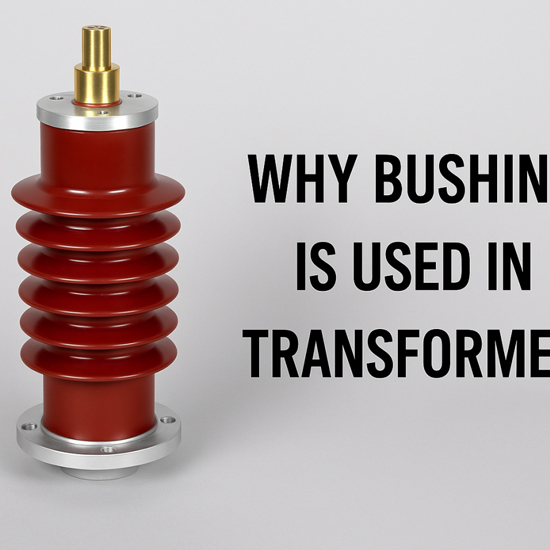

In every power transformer, the bushing may appear to be a simple insulator component—but its role is absolutely critical. Without it, high-voltage energy couldn’t safely pass through grounded transformer walls, and internal components would face a high risk of electrical failure.

So, why is a bushing used in a transformer, and what should buyers look for in choosing the right one?

A transformer bushing acts as the electrically insulated pathway between the live conductor and the grounded transformer tank. It must:

Withstand high voltage (up to 35kV, 66kV, or higher)

Isolate internal windings from external environment

Prevent oil or SF6 leakage

Survive thermal and mechanical stress over long-term operation

Bushings are not just physical connectors—they are dielectric barriers, sealing points, and structural anchors.

In recent years, transformer failures caused by bushing breakdown have become a key reliability focus. That’s why users now pay more attention to:

Creepage distance (especially in polluted environments)

Partial discharge performance

Epoxy or porcelain body quality

Pre-tested units with factory certificates

Many engineers also prefer pre-assembled wall bushings, reducing the risk of field installation error.

One commonly specified model is the 35kV wall bushing with epoxy insulation and embedded conductor. It’s widely used in:

Oil-immersed transformers

Compact substations

High-voltage switchgear cabinets

With PUTAI Electric’s epoxy bushings, users benefit from:

·Low partial discharge (≤5pC)

·Precise mold casting

·Silicone oil compatibility

·And most importantly—tight delivery control

For procurement teams, it’s not just about specs—it’s about trust. Many customers in Southeast Asia, Middle East, and Africa work with PUTAI Electric because the company offers:

Decades of manufacturing experience in epoxy insulation

Customizable mounting interfaces

Reliable delivery even during peak seasons

Multi-stage testing including HV withstand and oil immersion

It’s not just a product—it’s peace of mind during your transformer project.